Basics to Making Cheese:

The 3 essential steps of cheesemaking:

1) Curdling, coagulation of the milk.

2) Draining, partial drawing off of the whey.

3) Ripening, conversion through microbial maturing of  the mass of curd obtained after draining.

the mass of curd obtained after draining.

HOW WE MAKE CHEESE

Très Belle Chèvre

Goat Dairy & Fromagerie

Cheese making is the process of removing water, lactose and some minerals from milk to produce a concentrate of milk fat and The milk must be manipulated in order to encourage the separate milk into its curds (solid) and whey (liquid). protein.

Impeccably clean, fresh, whole, milk is essential to making fine cheese. High quality cheese cannot be produced from inferior milk. Our milk is clean, fresh and wholesome.

1. Pasteurize

Most cheese produced and sold in the US is produced from milk that has been pasteurized. In the state of Louisiana, milk used in cheese making must be pasteurized if cheese is less than 60 days old. Pasteurization is one of the major critical control points in the cheese making process. It guarantees the milks safety by destroying the pathogenic micro-organisms that may be present in the raw milk. In order to pasteurize we utilize a double boiler method, which includes a pasteurization vat incased in a wall of water, an agitating paddle, thermometers and time-temperature recording charts. The milk is heated to >155° F and maintained at that temperature for 30 minutes. The milk is than cooled to a lukewarm temperature of anywhere from 75° to 86°F (depending on cheese type or given recipe).

2. Addition of the Starter Culture:

A freeze-dried DVI mesophilic starter culture is added to the warm (75-85°F) milk. Starter cultures are the prepared inoculate of bacteria, yeast and moulds, not dissimilar to those used to make yoghurt. Beneficial cheese-making bacteria occur naturally in raw milk, however since milk must be pasteurized, some of the favorable bacteria is destroyed, thus, the lactic bacteria must be re-introduced to the pasteurized milk via starter culture. A target temperature between 75-85°F is a hospitable environment for milk sugar-loving lactic acid bacteria. The milks’ warm temperature provides the perfect environment to activate the lactic bacterium that begins to attack the milks lactose sugar, thereby, turning it into lactic acid.

---Introduction of Surface Molds

In order for microbial enzymes to be fully effective during the ageing process, cheese acidity must be reduced and neutralized. To trigger the neutralization of the cheese body during the aging process, surface development of mold is encouraged with the early inoculation of the cheese with Penicillia type yeasts and molds. Usually, the milk is inoculated with yeasts and mold at the same time as the starter culture. These molds are principle de-acidification agents that will, during the first phase of ripening, consume the lactic acid and raise the pH level of the cheese body. Our soft-ripened, bloomy-rind cheeses owe their characteristic flavor, body and texture qualities to the predominating activity of one or more these agents introduced in the early stages of cheesemaking.

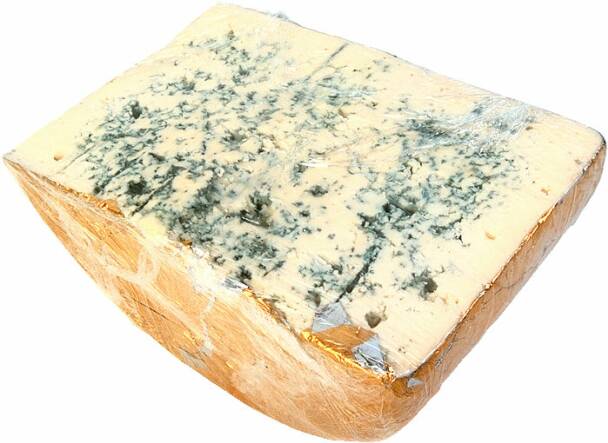

---P. Candidum, G. Candidum & P. Roqueforti

Geotrichum Candidum and/or Penicillium candidum are agent used to inoculate all our bloomy-rind cheeses. The strain of G. candidum and/or P. candidum that predominates on the exterior of our bloomy-rind cheese helps to determine the texture, cohesiveness, and thickness of the rind. Penicillium roqueforti, is a blue mold added during the molding process in order to introduce a distinctive blue veining and flavor to our blue cheeses. One or more of these various agents may be added to the cheese vat or directly to still draining individual cheeses in order to establish specific molds or yeasts in our specialty cheeses. For instance, G. candidum’s lipases and proteases promote flavor development, and reduce the bitterness imparted by low-molecular-weight peptides in cheese. Lipase added to milk when making feta helps give the cheese its distinct “feta like” taste. Introduced bacteria, fungi and lipases contribute to the development of distinctive flavors, textures and other desirable qualities.

After the addition of starter cultures and inoculants there is generally a ripening period of just a few hours or longer, depending upon the recipe being used, condition of the milk and type of culture added. The addition of starter culture helps in the development of the acidity that promotes ripening.

3. Rennet, the Curdling Agent

Rennet is an enzyme present in the stomach of all milk-fed animals. To produce a firmer curd, essential for the production of our cheeses rennet is added a little after the starter culture. The starter culture begins to develop the acidity necessary to stimulate the fermentation/souring process. Following the addition of the rennet coagulant the goat milk is allowed to rest undisturbed. This can take anywhere from a few hours to 2 days. The acidity of the milk promotes curdling, helps expel the liquid whey, and stems the growth of undesirable bacteria, and also adds to the flavor of the cheese. During this period the casein protein curdles and forms soft cheese curds. The curds are ready to cut (required in some recipes), hang in cheesecloth and/or ladle into molds.

4. Cutting the Curd

Proper cutting can be extremely important to both cheese quality and yield. The improper cutting and handling of the curd could cause the loss of small curd particles. Both early cutting when the curd is fragile and late cutting when the curd is brittle will cause losses of particles, thereby effecting quality and yield. The curd is ready to cut when whey begins to rise to the top of the gelled curd. At this stage the curd display a “clean break”. A “clean break” is accomplished when the flat blade of a knife is inserted at a 45 degree angle to the surface and then raised slowly. Curd size has a great influence on moisture retention, so the cutting procedure should be preformed carefully.

5. Draining the Curd

Once the desired consistency or stage of development is reached the curds are drained according to the recipe for particular cheese. For fresh chèvre the curds from our 28-gallon pasteurizer/cheese vat are ladled directly into cheesecloth lined colanders. When full the filled cheesecloths are tied and hung above whey collecting buckets to drain. There are usually 11 or so cheesecloths draining for each 28-gallon batch of chèvre.

---Small Batches

For specialty cheeses, such as our hand-salted feta and our line of soft, mold-ripened bloomy-rind cheeses, we use a small 10-gallon vat/pasteurizer. Some recipes call for cut curd, some recipes not. For bloomy-rind cheeses, curd is ladled from the vat into individual molds (logs, pyramids, cylinders, disks, etc.). Making beautiful and flavorful artisnal cheese can be quite labor intensive. It can take as long as 3 ½ to 4 hours to carefully ladle slices of curd into 24 log molds for our St. Margaret and Bûche de Chèvre! Whey drips into collection pans positioned under the molds. The greenish-yellow colored whey expelled from the cheese is fed to the goats as a nutritious supplement. Cheese is turned according to the recipe. The curds remain in the cheesecloth or molds for 24 to 48 hours becoming firmer as more whey drains out.

6. Salting & Charcoal

After the mold forms are removed each bloomy-rind cheese ( Lil’ Gracie, Buche de Chèvre (aka Taunte Cecile), Brossard, St. Pete, and Barely Bleu and Bayou Bleu) is generously hand-salted and placed on drying/curing racks before placing in ageing refrigerators. Our St. Margaret, Fuselier, Kennicay and Chiminee Ecrevisse are dusted with a combination of charcoal ash and kosher salt. Sprinkling the surface of the cheese with charcoal powder, which contains potassium will de-acidify the cheese body. Potassium possesses properties, which decrease body acidity, and encourages the enzyme activity necessary for maturation.

---Salt for Chèvre

Salt is also incorporated into our fresh chèvre before packaging. The purpose of salting is to: inhibit the growth and activity of pathogenic and food-poisoning microorganisms; inhibit the activity of various enzymes in cheese; reduce the moisture of cheese; change cheese proteins which influence cheese texture and protein solubility; and affect cheese flavor. At this point some cheeses, like our fresh chèvre, are ready to eat. At this stage the chèvre is fresh and mild in flavor. Our bloomy-rind cheeses will be cured and aged further.

7. DRYING

Cheeses are arranged on a curing/drying rack at a temperature of approximately 64° to 68° F and a humidity of approximately ±65%. The cheese will remain there for anywhere from one to four days. Each cheese is turned daily to ensure even draining and curing.

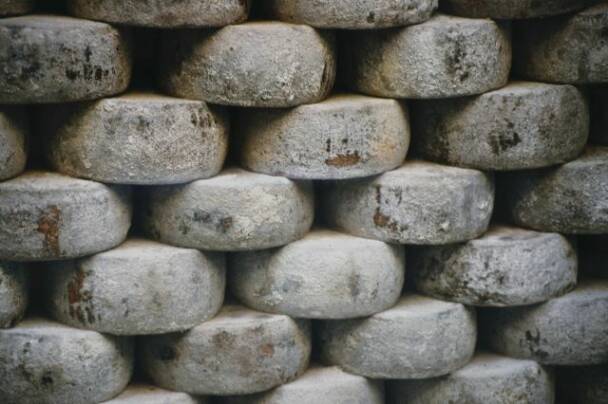

8. RIPENING

After a few days out drying/curing at 65 ° cheeses are finished curing at a lower temperature, and higher humidity, curing refrigerator. This environment encourages the white mold to bloom on the outside of the cheese. Then the cheeses are then wrapped in specialized cheese ageing papers and placed in ageing refrigerators at 53°F and __% humidity. Cheese ripening exposes the prepared cheese to certain environmental conditions (temperature, humidity and so on) for a few weeks to several months depending on the cheese type. The purpose is to break down the proteins, lipids and carbohydrates (acids and sugars), which releases flavor compounds and modifies cheese texture. Hand salted feta is ripened anywhere from one to 2 weeks before packaging for market. Our soft, mold-ripened, bloomy-rind cheeses are turned regularly and aged anywhere from 2 weeks to 60 days, depending on the maturity required in the final product. For instance, Our Lil’ Gracies are ripened for 2-3 weeks to a month. We begin bringing them to market at 2 weeks. When ready for market each cheese is labeled and sold by the ounce.

9. SKILL

Skill is an absolute requirement for making quality cheese. Beautiful, flavorful, aromatic cheese requires constant assessment and meticulous care on the part of the cheese maker. With consistency and dedication one eventually develops a “feel” for the cheese. In time the alert and observant cheese maker is able to “read” the developing cheese by its smell, the way it feels to the touch, how it looks. The eventual development of a cheese makers “sixth sense” is the hard won skill rewarded the cheese maker after years of dedication and commitment.

---CONCLUSION

There are many factors that can have an effect on cheese making and the final cheese product. Just as the nature of the milk from which it is made causes variations in the characteristics of the cheese, so can modifications of production methods and environmental changes. For example, breed of goat, diet eaten by the goat herd, and herd health may influence milk and cheese quality and flavor; season, climate, atmospheric conditions, water quality, recipe variation and even the mood and personality of the cheese maker can in one way or another have a negative or positive effect on the final cheese product. Artisan and Farmstead Cheese Makers and the cheeses they lovingly produce are a varied lot. There are no two cheese makers who posses the same skills or expertise. Interestingly, no two cheeses, even when comparing somewhat similar cheeses made by different cheese makers have identical aroma, texture and flavor. Cheese making and cheese appreciation can prove to be quite an adventure, a very satisfying adventure that involves ALL the senses. Get to know our cheeses and begin your cheese adventure. A world of pleasure awaits you.